Home

Print-Tech®

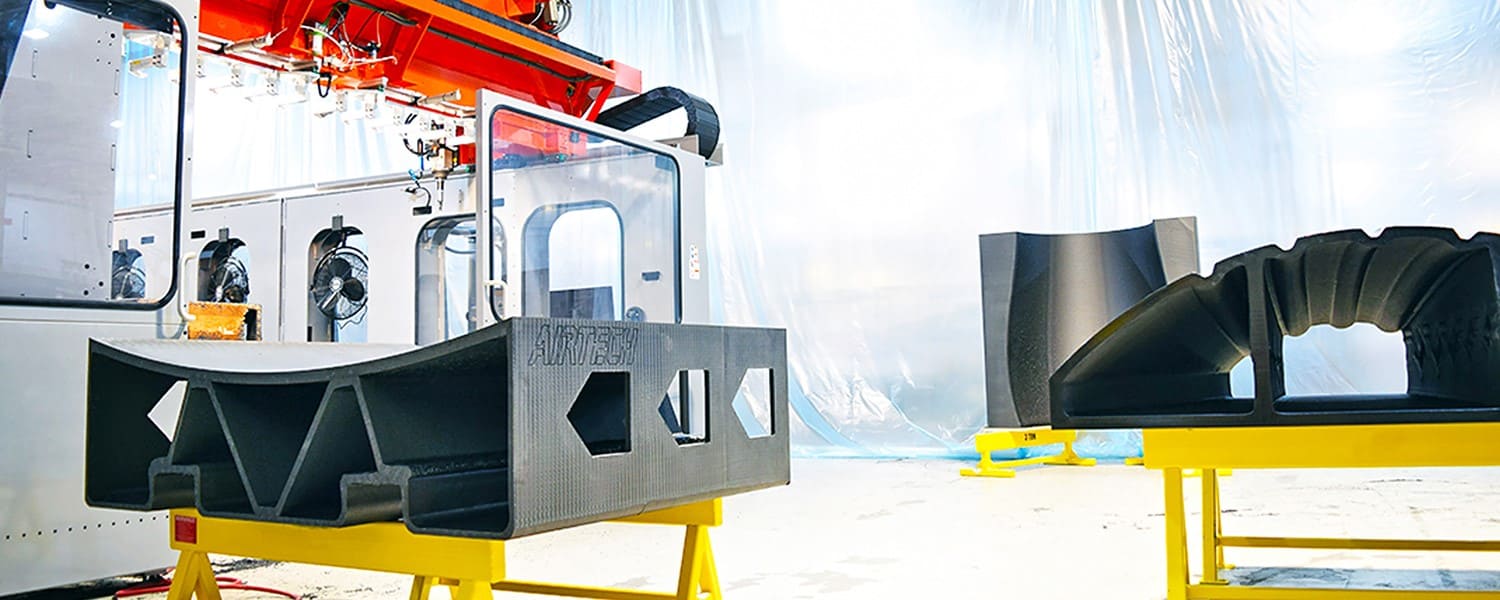

Airtech expertise has added value to Large Scale Additive Manufacturing and taken it to the next level. Airtech is utilizing its facilities in Springfield, TN (USA) and Differdange, Luxembourg to house a pair of 40ft x 10ft (12m x 3m) large scale additive manufacturing machines to offer its Print-Tech® full-service tool manufacturing solution. Exclusively with Dahltram® resins, in-house researched and developed specifically for advanced composite tooling applications.

- Innovation - Patent process innovations and trademark products for unique high temperature and room temperature applications.

- Lead Time - Rapid tooling from design to the production floor in significantly less time than conventional methods.

- Cost - Substantial reduction in touch labor and material waste for significant savings.

- Scale - Diverse solutions with large scale 3D printing capability.

Manufacturing Expertise

- World leader in extrusion of high temperature polymer films for composites

- Large area CNC machinery, up to 23ft x 197ft (7m x 60m) has been the basis for our Engineered Materials for Lean manufacturing service

- LSAM Additive Manufacturing relies on CNC controlled thermoplastic extrusion, core competencies of Airtech

- Airtech expertise continues to add value to Additive manufacturing

Materials Expertise

- Thermoset & Thermoplastic resin experience based on nearly 50 years of extrusion experience.

- Resin formulation capability and quality control.

- Our in-house compounding, bespoke materials, niche applications

- Tooling material & process expertise in multiple applications (e.g. Wet process, Infusion, Prepregs & Automated lay-up)

Dahltram® Tooling Resins

Airtech has developed a new series of innovative polymer composite resins, Dahltram® for use in large scale 3D printing that has addressed the need for lower CTE and a more robust service life when used at low or high temperatures, including use in an autoclave. These thermoplastic composite resins are designed for use in any pellet fed FDM printing system.

- Resin selection - Range of resins available for high and low temperature applications.

- Resin properties

- Carbon reinforced for added stiffness and stability

- Low thermal expansion

- In stock - Materials in stock for immediate shipping

For more info, please see our catalog or contact us, we are ready to assist you with all of your 3D printing needs!