Print-Tech® : Additive Manufactured Tooling for Composites

Print-Tech®

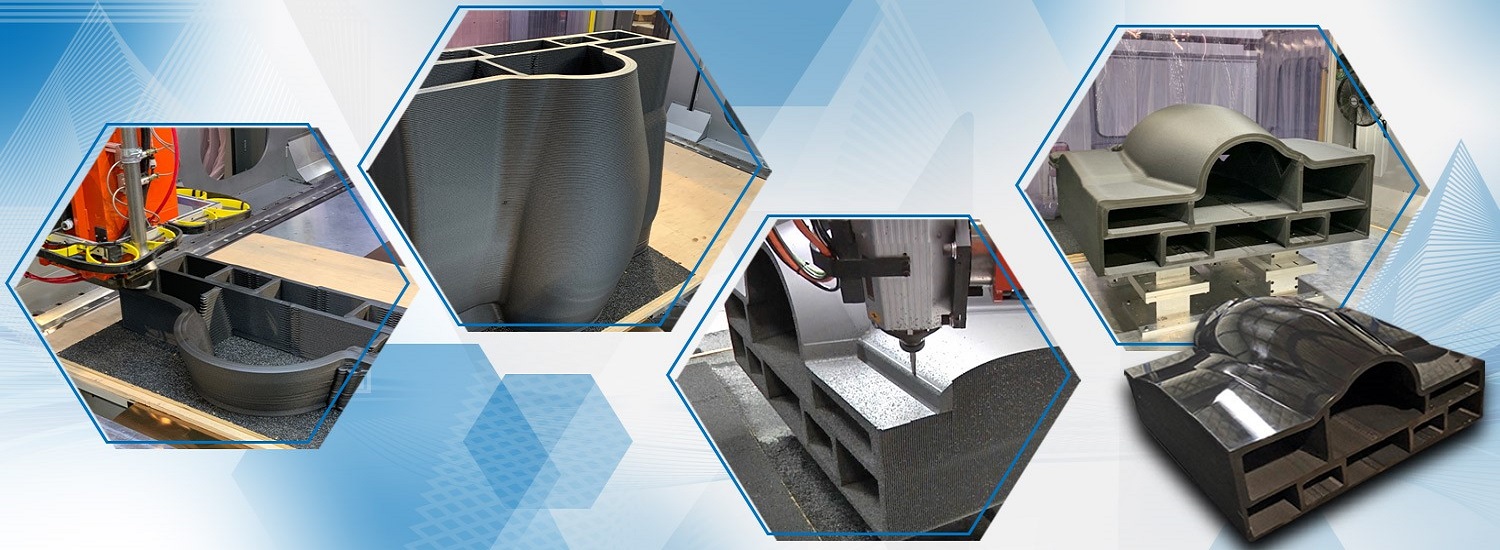

Airtech expertise has added value to Large Scale Additive Manufacturing and taken it to the next level: Print-Tech® is our full-service of composite tooling manufacturing solutions.

The high throughput and relative low cost manufacturing method of Fused Deposition Modeling (FDM) is used to create large tooling structures and surfaces for low to high temperature lay-up molds, trim or assembly fixtures, or masters. These demanding tooling applications require the structures and the materials they are made from to be durable and dimensionally stable.

Tooling on the shop floor faster than any other process

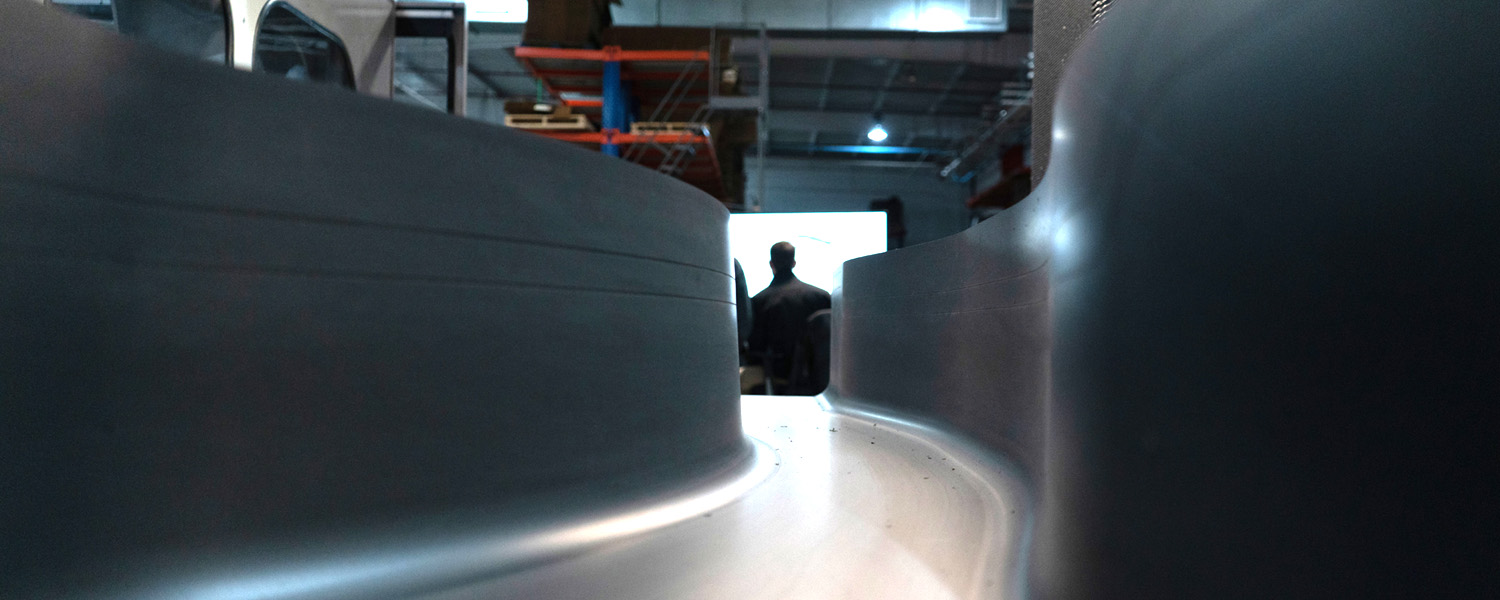

With our state-of-the art largest commercially available 3D printers 40ft x 10ft (12m x 3m) we take tooling from conception to shop floor reality significantly faster than conventional methods.

With high deposition rates and accuracy machining, large-scale tooling in the form of trim fixtures, holding fixtures, and layup molds can be designed, tooled, and built faster without compromising on quality.

Print-Tech® additive & subtractive tool manufacturing process greatly reduces touch labor, lead-time, and waste.

High deposition rates

Contact us, we are ready to assist you with all of your 3D printing needs!